The way the positioner is connected is designed to bring the part connected to it to the most suitable position for welding and welding.

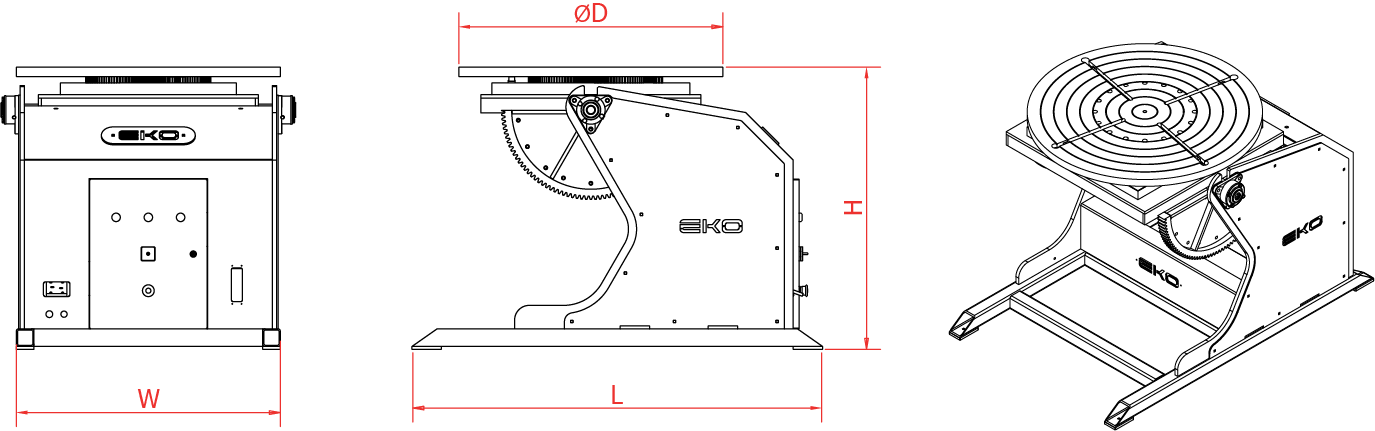

PE-2 axis positioner systems are mechanical systems that enable workpieces to be brought to the most suitable position in welding, assembly and machining processes. These systems offer the ability to move in two independent axes. The system performs rotation and angular positioning functions precisely.

Designed to enable operators to work more comfortably and more efficiently in welded manufacturing processes, this system offers a vibration-free and safe process by balancing according to the center of gravity of the workpieces. These systems are preferred for welding large and heavy workpieces and minimize operator fatigue while increasing speed and quality in production processes.

PE-2 axis positioners offer high performance in heavy industrial production environments with their strong body structure, precise speed control and durable motor systems. Power transmission is optimized by using low backlash gears and gearboxes, while the low-voltage control system ensures safe working conditions.

These systems offer easy operation with digital or analog control options. They can also be integrated into automation systems and work in synchronization with different production equipment such as column booms.

The systems, which are used in welded manufacturing, grinding, assembly and quality control processes, maximize production efficiency while increasing occupational safety.

Widely preferred in modern industrial applications, these systems continue to optimize production processes by becoming smarter and more efficient with advancing technology.