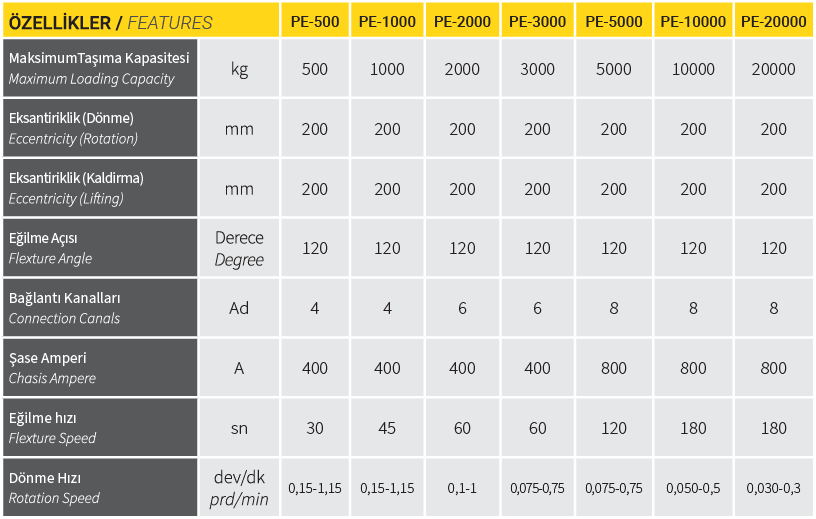

Chain type positioner systems are advanced mechanical systems designed for the rotation and positioning of large and heavy workpieces. These systems allow workpieces to be moved precisely up, down and at certain angles thanks to the chain mechanism. With its features, it minimizes the need for manual intervention, increases work safety and provides maximum efficiency in welding processes.

Chain type positioners allow both symmetrical and asymmetrical workpieces to be positioned safely thanks to their synchronized body structure. Equipped with user-friendly control mechanisms, these positioners are preferred in various applications such as welding, assembly and grinding in modern industry, maximizing quality and safety in production processes.