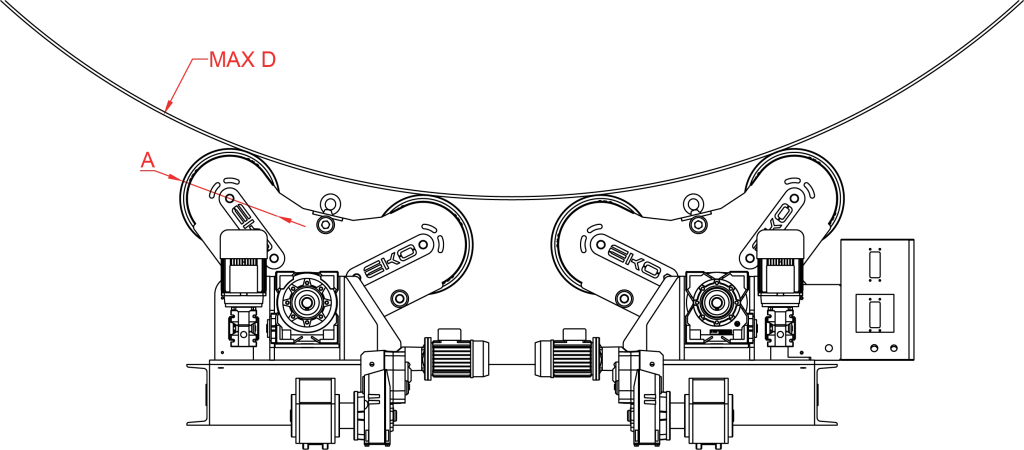

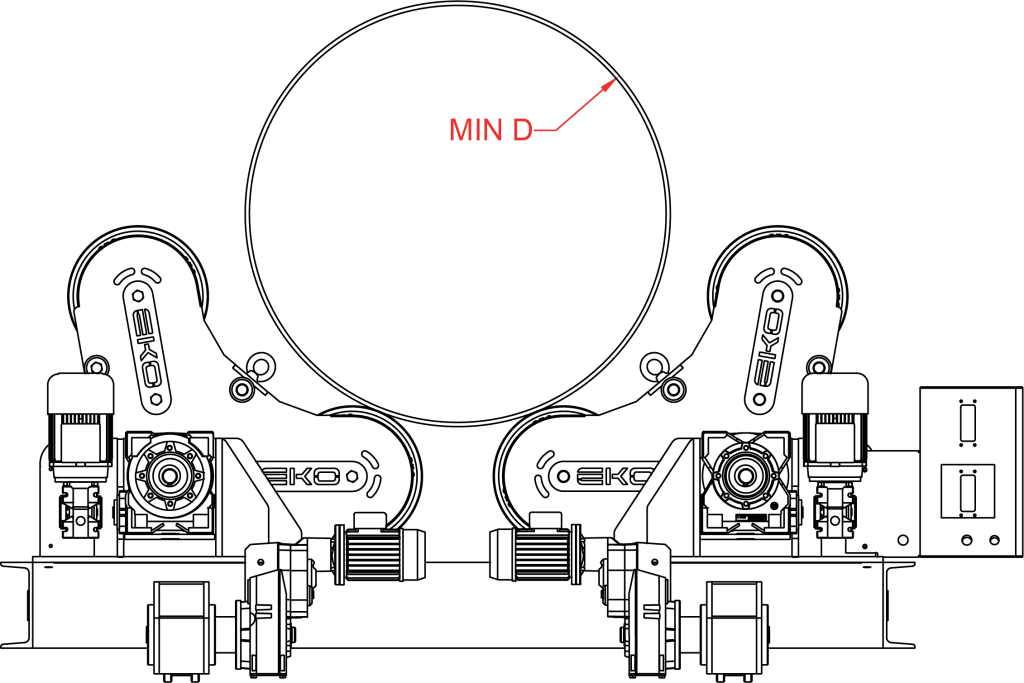

Self-adjusting rotator systems are advanced mechanical systems that provide automatic centering of cylindrical workpieces of different diameters and sizes and offer precision in welding processes. Unlike conventional systems, these systems reduce the operator’s workload by automatically adapting to the diameter of the workpieces without the need for manual intervention.

Used for welding large diameter pipes, tanks and heavy industrial equipment, these systems improve welding quality by providing a stable and vibration-free rotational motion.

Self-adjusting systems are equipped with motorized drive mechanism and hydraulic adjustment units and have a high carrying capacity. Polyurethane-coated wheels ensure smooth rotation of the workpieces during welding, increasing impact resistance. The system’s precise speed control and digital remote control options allow operators to easily manage the system.

Self-adjusting rotator systems can work in synchronization with column boom systems and other welding automation equipment, helping to save time and optimize costs on production lines.

Widely used in many areas of industry, including pipe production, tank manufacturing, shipbuilding and welding of heavy industrial equipment, this system has become an indispensable part of modern industry by increasing work safety and production efficiency.

These systems, which have become more precise, safe and automated with today’s developing technology, guarantee quality and continuity in industrial production processes.