H beam welding systems are automation solutions designed to speed up the welding processes of H profiles used in structural steel production and to perform them with high precision. These systems optimize production processes by welding both surfaces of the profiles simultaneously. Thanks to their hydraulic fixing mechanisms and automatic torch positioning features, they enable easy processing of H beams of different sizes and maximize welding quality.

H beam welding systems play a critical role in increasing the durability of structural steel profiles used in the construction, shipbuilding and heavy industry sectors. Equipped with conveyor-assisted transport mechanisms and submerged arc welding technology, these systems offer high efficiency in linear and angular welding of H-beams. With a flexible design that adapts to various dimensions, H beam welding systems offer an innovative solution that meets modern production needs.

H beam welding systems are innovative automation solutions used in the production of structural steel elements and provide high precision. Used especially in the construction, shipbuilding and heavy industry sectors, these systems can perform welding operations on both linear and angular surfaces of H-beams. This is critical for the durability and safety of structural elements.

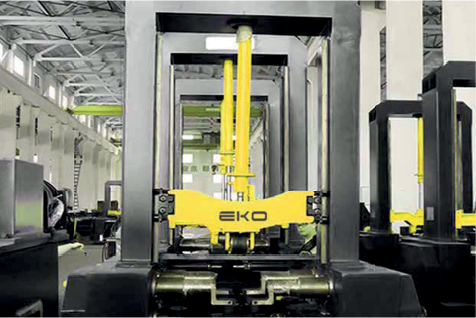

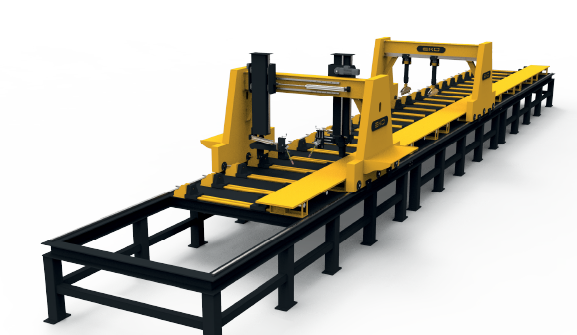

The system is designed for the production of H profiles of different sizes and is equipped with mechanical rails that ensure high precision. The welding heads are fixedly positioned and the workpiece is moved by means of conveyors. This allows simultaneous welding on both sides of the profiles. Hydraulic cylinders ensure that the H-beams are firmly fixed and maintain their position during welding.

The conveyor groups used in the H-beam welding systems are equipped with adjustable resting arms and hydraulic piston loading units. These features allow easy handling and positioning of workpieces. In addition, the beams can be rotated 90 degrees with the chain or mechanical construction of the system, which offers additional flexibility for the welding process.

In these systems, submerged arc welding machines can be integrated and the position of the torch mechanism can be precisely controlled throughout the welding process. The mechanical slide system allows the welding heads to automatically move closer and further apart, so that profiles of different sizes can be easily processed. H-beam welding systems optimize production processes and reduce costs thanks to high precision, durability and user-friendly design.