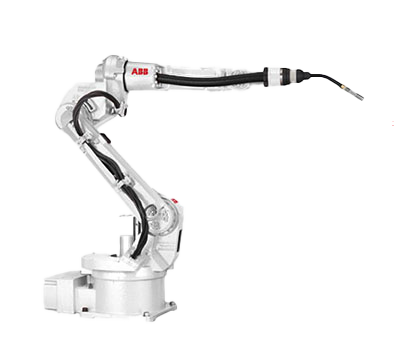

ABB Welding Robot IRB 1520ID is an advanced technology robot designed to make industrial welding processes more efficient and precise. Thanks to the integrated hose package, elements such as power, welding wire, shielding gas and compressed air are integrated into the robot’s structure, providing a more organized and safe working environment. This innovative design offers consistent performance, high precision and long life in welding processes, creating great advantages in production lines.

ABB Welding Robot IRB 1520ID can work effectively even in tight spaces with its compact structure and flexible mounting options. With a 4 kg payload capacity and a reach of 1.5 meters, it has a wide range of applications in different welding applications. Equipped with ABB’s TrueMove™ and QuickMove™ technologies, this robot optimizes production processes by offering excellent trajectory accuracy and fast cycle times. It also integrates with ABB’s advanced programming and simulation software for a user-friendly experience.