Submerged arc welding wire is commonly used in heavy industry to create deep and solid weld seams. This type of wire offers a durable solution especially for joining thick materials.

Submerged arc welding wire covers the metal with flux during the welding process, cutting off oxygen contact. This results in a cleaner and more durable weld seam. These wires, which come in various alloys and diameter options, are suitable for many applications.

Submerged arc welding wires stand out with the following advantages:

- Provide high melting efficiency, thus reducing process time.

- Create smooth and aesthetic seams, reducing post-weld operations.

- Offer functional solutions, increasing structural durability.

- Can be adapted to industrial needs, offering performance boosts tailored to specific projects.

- Directly influence welding performance and contribute to raising quality standards.

What is Submerged Arc Welding Wire?

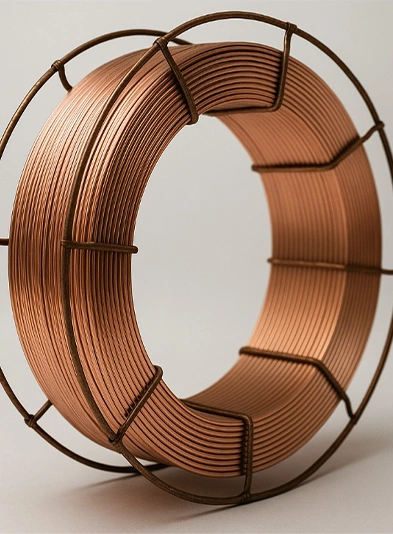

Submerged arc welding wire is one of the key components of automatic welding systems that facilitate the joining of heavy and thick materials used in industry. These systems operate under high current and voltage to ensure strong fusion of metals. Its copper coating increases electrical conductivity and resistance to corrosion; this feature enhances industrial efficiency and welding quality. The protective material used during the welding process is submerged arc welding flux; this flux protects the molten metal and ensures the quality of the weld seam

One of the materials used during the welding process is special protective flux. These fluxes not only isolate the weld seam from external factors but also improve the structure of the molten metal. Welding fluxes, offered in various particle sizes and compositions, maintain the stability of the weld pool and reduce the risk of spatter.

This technology is an effective solution not only for flat plates but also for the assembly of large-scale metal structures. Thanks to this technology, significant advantages in terms of time and quality are achieved in the assembly of pipes, ships, and steel constructions. Forming smooth and solid weld seams over large surfaces is especially critical in heavy industry.

Main factors that improve welding efficiency include:

- The welding wire used in the production field is automatically delivered to the welding area through wire feeding systems.

- This wire, working in conjunction with the submerged arc method, ensures smooth, durable, and deep weld seams.

- Offering wires in different alloys provides flexibility depending on the application area and increases efficiency.

In projects that require high performance, the mechanical strength of the welding wire is extremely important. Especially when joining components made of high-strength steels, the welding material must have the same level of strength. Therefore, selecting the right wire and appropriate welding parameters is critical to achieving weld quality.

How is Submerged Arc Welding Wire Used?

During the submerged arc welding process, the welding wire is automatically fed into the welding area and used with a special welding flux. This flux not only isolates the weld seam from external factors but also improves the structure of the molten metal. Welding fluxes, available in different particle sizes and compositions, help maintain the weld pool’s stability and reduce the risk of splatter.

What Are the Types of Submerged Arc Welding Wire?

Submerged arc welding wires are offered in various alloys and diameters according to their usage areas and requirements. For instance, special wires are preferred for stainless steels, while different alloys are used for high-strength steels. Additionally, copper-coated wires improve both electrical conductivity and resistance to corrosion.

What Should Be Considered When Choosing Submerged Arc Welding Wire?

- Material Compatibility: Choosing a wire suitable for the type of material to be welded is essential.

- Alloy Properties: The appropriate alloy wire should be selected according to the desired mechanical properties.

- Diameter Selection: The wire diameter required for the welding process should be accurately determined.

- Application Area: Wire selection should match the usage area (e.g., shipbuilding, steel construction).

For customized submerged arc welding wire solutions, you can contact Eko Kaynak.