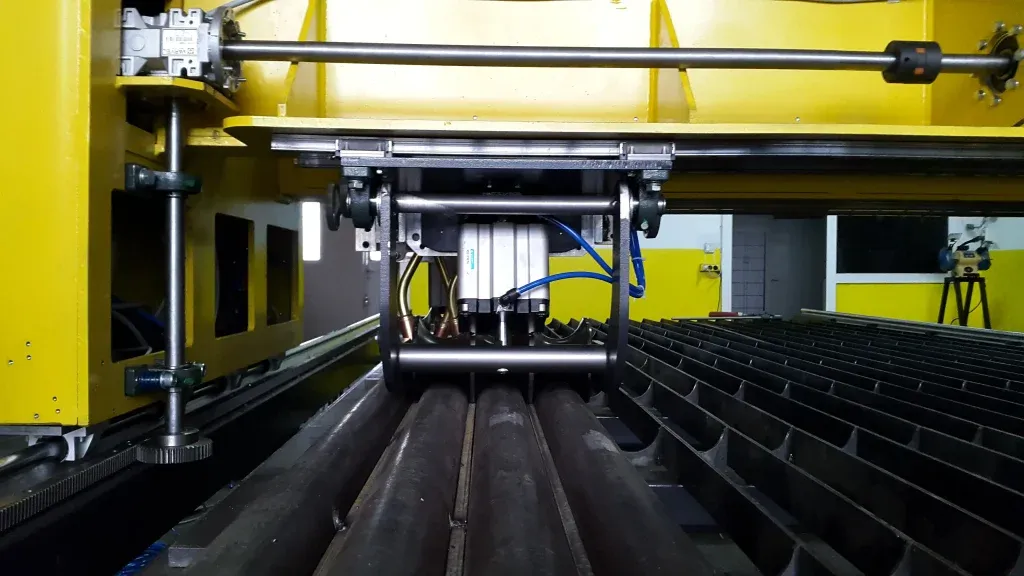

Membrane panel welding systems are technological solutions developed for high-precision and durability-demanding production processes, especially in the construction and industrial sectors. These systems are primarily used to join metal surfaces—such as steel or aluminum—through welding, enabling the production of panels that are aesthetic, sealed, and durable. Their automation-supported design makes them suitable for mass production while ensuring standardized product quality.

Thanks to advanced welding heads, heat control systems, and robotic arms, maximum efficiency is achieved with minimal human intervention. Additionally, these systems reduce operational costs through energy efficiency and low maintenance requirements. Membrane panel welding systems are commonly used in the production of sandwich panels, cold storage walls, and sound insulation panels. They increase production efficiency in modern facilities and simplify quality control processes. High-quality weld seams not only enhance durability but also ensure the long service life of the final product.