H-beam welding systems are automation solutions designed to accelerate and precisely execute the welding processes of H-profiles used in structural steel production. These systems optimize production workflows by welding both sides of the profile simultaneously. With hydraulic clamping mechanisms and automatic torch positioning features, they allow for seamless handling of H-beams in various sizes, significantly enhancing weld quality.

H-beam welding systems play a vital role in reinforcing the structural integrity of steel profiles used in construction, shipbuilding, and heavy industry. Equipped with conveyor-assisted transport mechanisms and submerged arc welding technology, these systems provide high efficiency in both linear and angular welding operations. Thanks to their flexible design that accommodates various dimensions, H-beam welding systems offer an innovative solution that meets the needs of modern manufacturing.

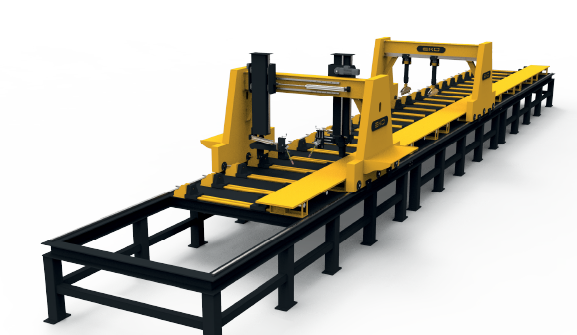

*The H-beam system is produced not only in vertical form but also with a horizontal clamping system.