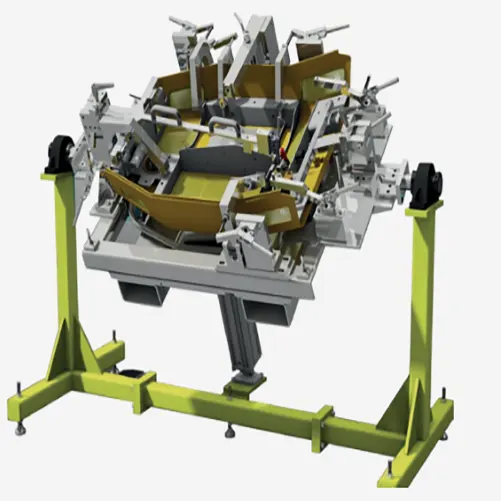

Welding Fixture

Welding fixture refers to special equipment used in industrial production processes to correctly position and secure parts. These systems prevent parts from slipping or misaligning during welding, ensuring the process is carried out in a more controlled and reliable manner.

Welding fixture is one of the most important auxiliary tools that reduces time loss on mass production lines and ensures consistent product quality. While allowing metal parts to be joined compatibly, it minimizes operator errors. It can also be specially designed for parts of different sizes and shapes. When integrated with robotic welding systems, high efficiency is achieved, and the production process becomes automated. In this way, occupational safety increases, and production costs decrease.

Welding Fixture Design

Welding fixture design ensures that parts are fixed in the correct position in production processes and that operations are performed in a repeatable manner. Used in industrial production, particularly in the automotive, metal processing, and heavy industry fields, these systems improve welding quality while shortening production time. During the design phase, the geometry of the parts, production tolerances, and operational requirements are taken into account.

For a welding process to proceed in compliance with standards, a fixture alone is not enough. In addition, welding apparatus also plays an important role. These devices support the correct securing of parts, minimizing the margin of error. As a result, labor costs decrease, and efficiency increases in high-volume production lines.

Key points to consider when designing a welding apparatus include:

- Correct alignment of parts before welding

- Ergonomic structure to provide ease of use

- Long-lasting use with durable material selection

- Possibility of integration with robotic systems

Welding jigs used in production lines allow parts to be secured in a repeatable way. Correctly designed jigs make the operator’s job easier and standardize welding quality. Jigs also offer flexible solutions for parts of different sizes.

A welding gauge is another auxiliary tool used to maintain measurement accuracy. Thanks to the gauge, the accuracy of the parts is checked, and post-welding errors are prevented. This increases quality assurance in production processes.

Welding apparatus designs go beyond just securing parts; they are an important element that improves quality in production, increases efficiency, and ensures process continuity.

Welding Fixture Manufacturing

In industrial production processes, manufacturing a welding clamping device is a critical stage to improve quality and ensure parts are joined in compliance with standards. The equipment used in this process must be durable, offer high precision, and have a long-lasting structure. During the manufacturing process, special solutions are developed by considering the dimensions of the parts, their intended use, and their position on the production line.

When fixture design is carried out correctly during production, possible errors during welding are minimized. Operators can also work faster and more safely. This reduces labor costs and increases overall efficiency. Especially in mass production, standardizing fixtures helps produce a large number of products with the same quality.

Key points to consider in welding clamping device manufacturing include:

- Use of materials resistant to high heat and impact

- Solid structure that ensures parts remain fixed during the process

- Easy disassembly and assembly feature for maintenance convenience

- Compatibility with other automation systems on the production line

An assembly fixture used in the industry ensures that parts are assembled correctly. Using these fixtures in assembly processes shortens the preparation time for welding operations and contributes to the serial production of products.

In heavy industry and the metal processing sector, a metal fixture also helps secure parts in the correct position. These fixtures stand out with their durability and can be customized for parts of different sizes and shapes.

Welding apparatus manufacturing is a fundamental process that improves production quality, saves time, and creates a safe working environment.

Frequently Asked Questions

They are special equipment that ensure parts are fixed in the correct position during welding. Used in different industries, these systems reduce the margin of error in production and standardize quality.

They are devices that ensure parts made of metal or other materials remain fixed without slipping or misaligning during welding. These systems save time, especially in industrial production, and are important in terms of occupational safety.

They are advanced systems that work integrated with automatic welding machines, ensuring parts are correctly held and welded by robotic arms. Thanks to their ability to provide high efficiency and repeatable quality, they are widely preferred in industrial automation.

For professional support in welding fixture design and manufacturing processes, you can contact Eko Kaynak.