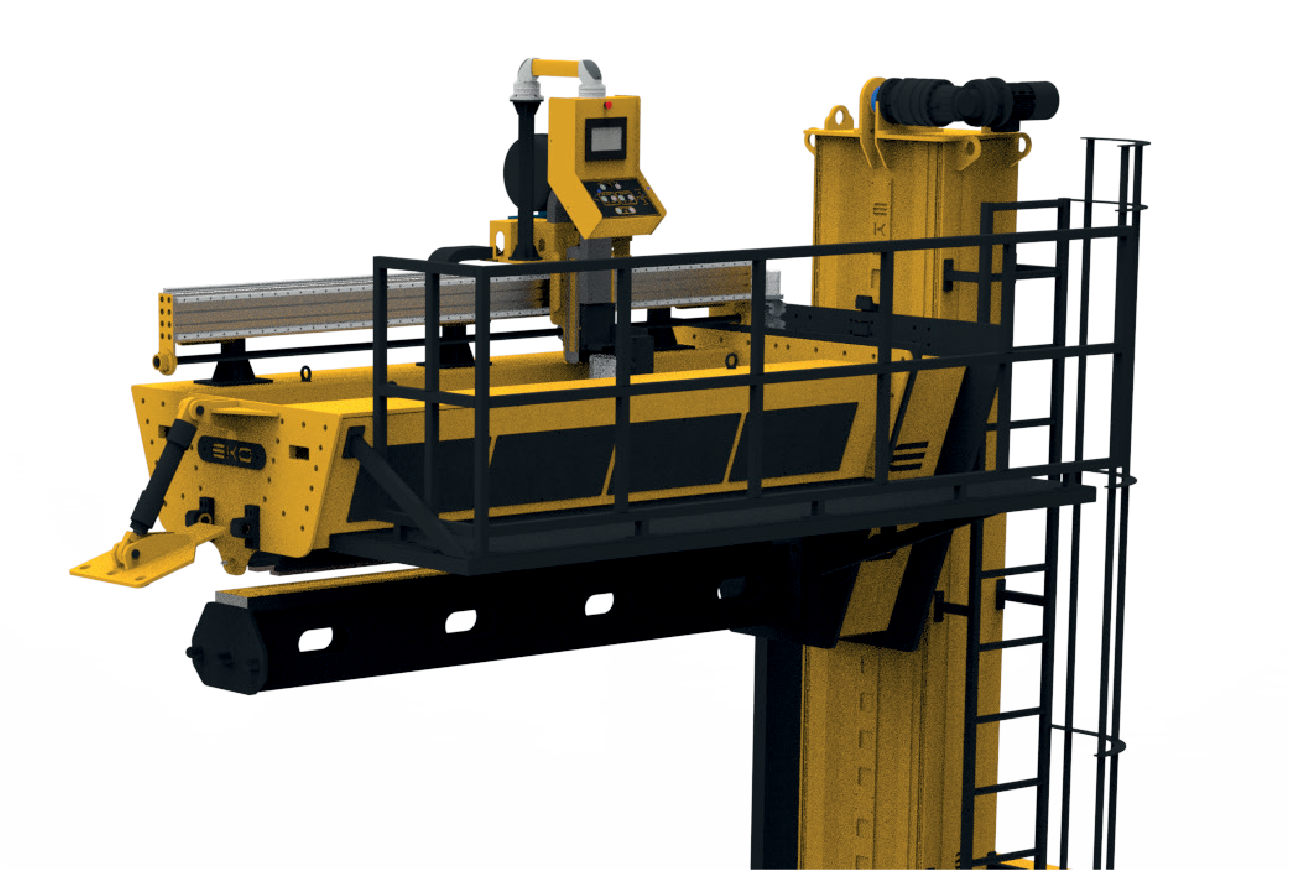

Outsize welding is an effective and innovative method for welding the outer surfaces of cylindrical workpieces. This process, which requires durability and precision in large diameter pipes, tanks and industrial equipment, provides high efficiency with modern automation systems. Supported by double welding heads and linear motion mechanisms, outsize welding systems increase production speed and raise quality standards to the highest levels. These technologies play an important role in sectors such as energy, shipbuilding and heavy industry.

Outsize welding is a technology developed to perform high-precision welding processes on the outer surfaces of long and wide workpieces. This method stabilizes the workpiece and ensures consistent weld seams along the axis. Ideal especially for businesses aiming to increase production capacity, outsize welding systems have a wide range of applications thanks to their ability to work in harmony with different welding techniques. Ergonomic design and digital control systems support operators to work efficiently.