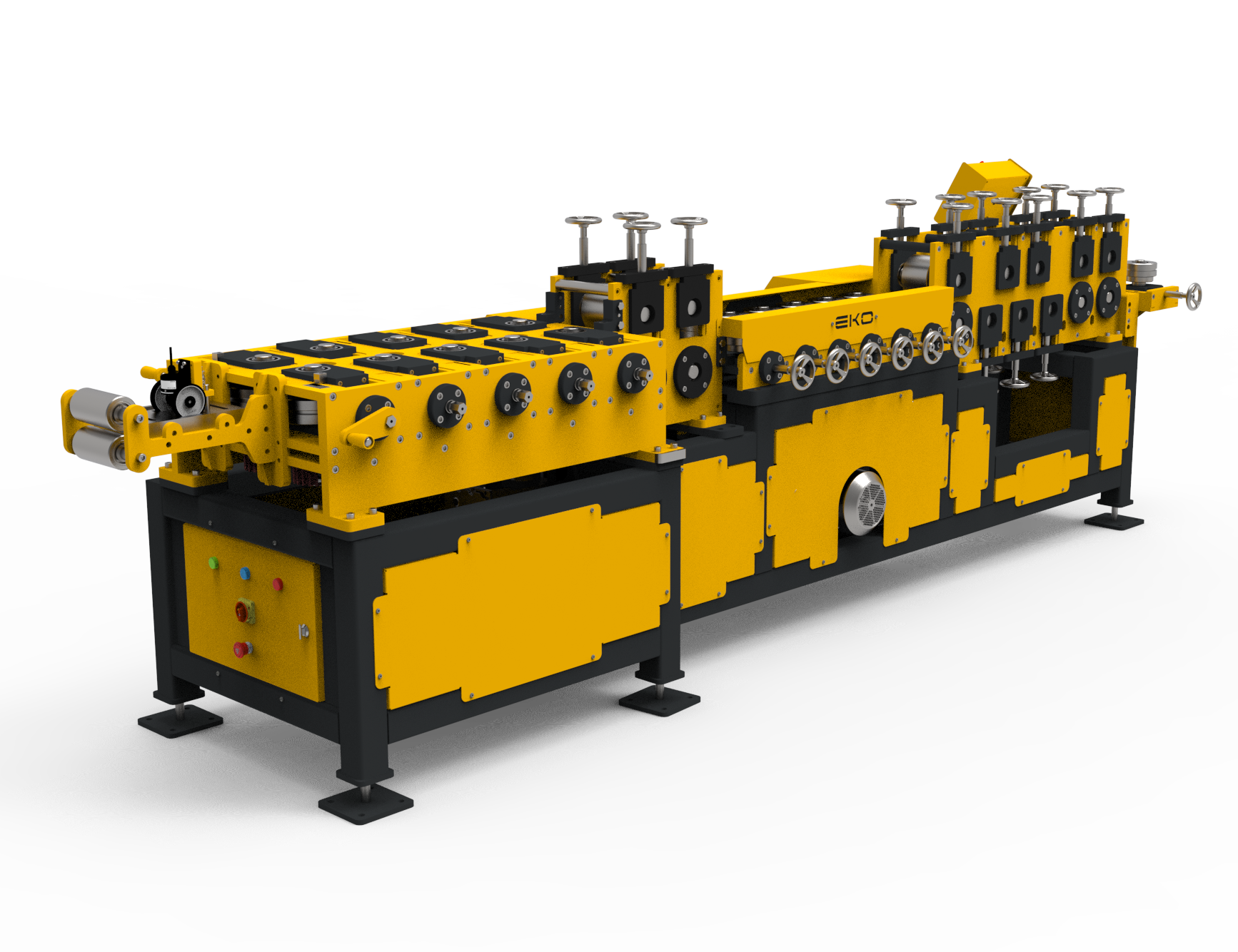

The flat bar straightening system is a precision device used in production lines to correct the deformation of metal strips. It is especially useful in processing coiled steel, aluminum, or stainless flat bar materials to ensure a flawless surface and smooth feed. By straightening the material and preparing it for cutting or welding, the system directly influences the quality of the subsequent manufacturing stages.

The flat bar straightening system is an essential component in production processes that require high accuracy. These systems operate with various roller configurations depending on the thickness, hardness, and intended use of the material and are widely applied in industries such as automotive, white goods, defense, and construction. With automatic adjustment systems, sensor-supported control mechanisms, and modular designs, they offer energy-efficient and operator-friendly solutions. This ensures continuous flow in production lines and minimizes material waste. Equipped with high-performance straightening technologies, these systems support sustainable manufacturing practices while contributing to product standardization.