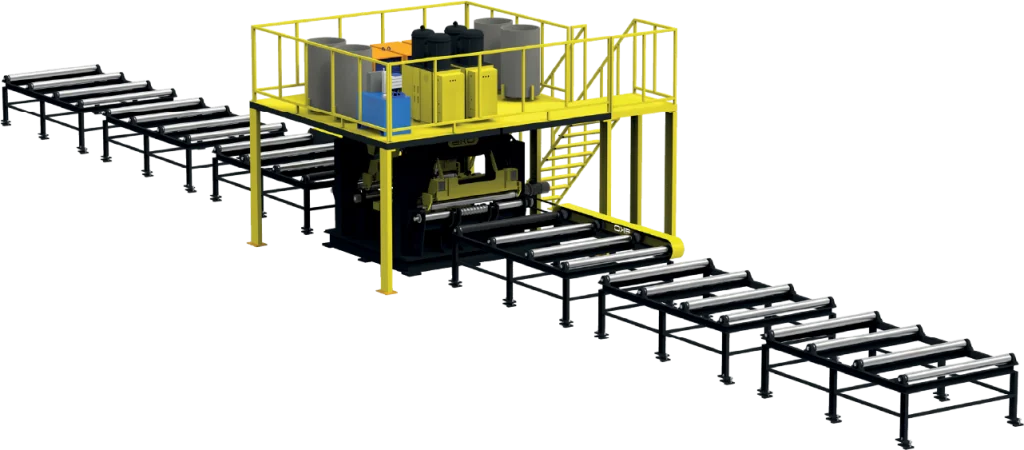

Membrane panel welding systems are an innovative welding technology that provides high precision and efficiency in the production of boiler membrane walls. These systems, which are used for joining pipes and slats of different diameters and thicknesses, increase production speed while optimizing weld quality. Membrane panel welding systems, which minimize operator errors thanks to their automatic positioning and fixing features, offer a reliable solution in industrial production.

Membrane panel welding systems are special automation systems designed to perform precise and fast welding processes in modern production processes. Especially in the energy and industrial sectors, it increases the welding quality by facilitating the joining of pipes and slats. With the ability to perform double-sided welding and integrated control mechanisms, these systems increase occupational safety and production efficiency while reducing costs.