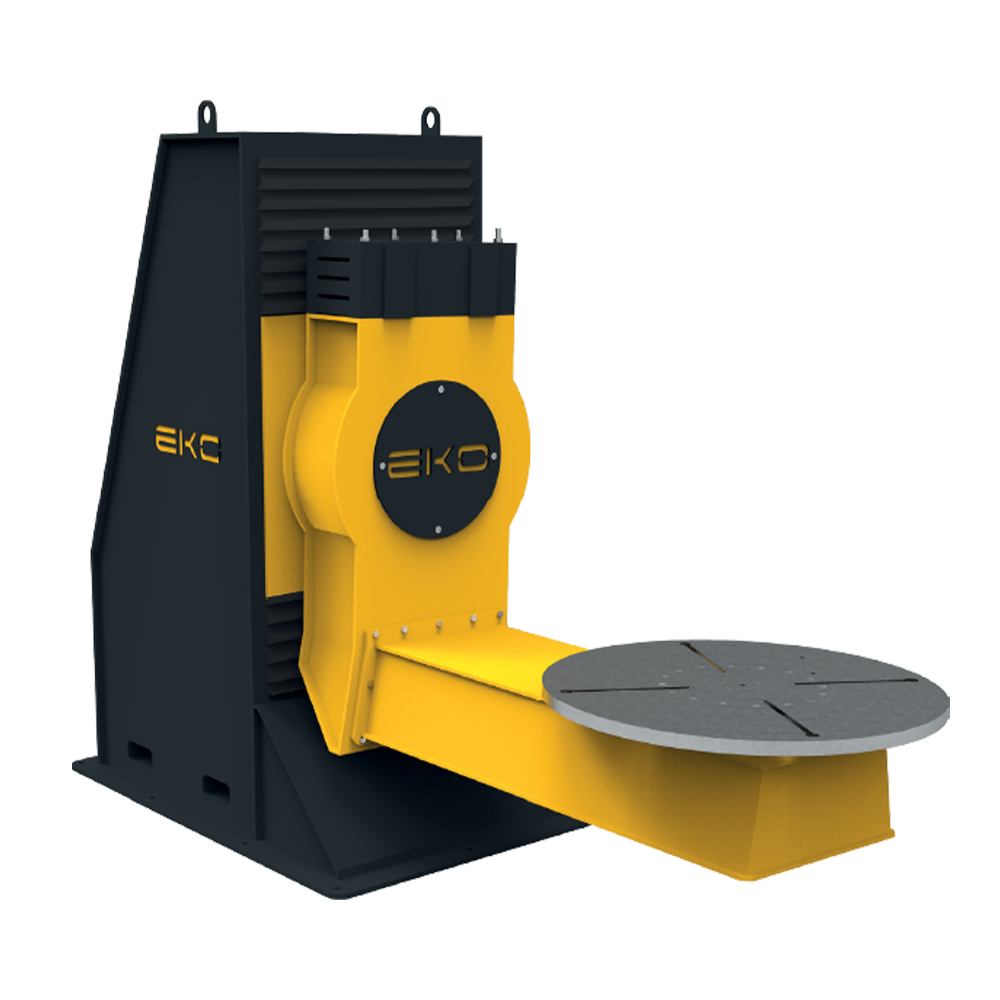

Positioner systems are mechanical devices used in welding operations to position workpieces in the most optimal orientation. These systems offer multi-axis movement capabilities such as rotation, angular positioning, and height adjustment, enabling operators to perform more precise and higher-quality welds.

In industrial production, positioner systems provide significant advantages in terms of workplace safety and ergonomics. By eliminating the need for operators to manually rotate and position large workpieces, they help minimize the risk of workplace accidents. These systems are an essential component of modern industrial manufacturing.