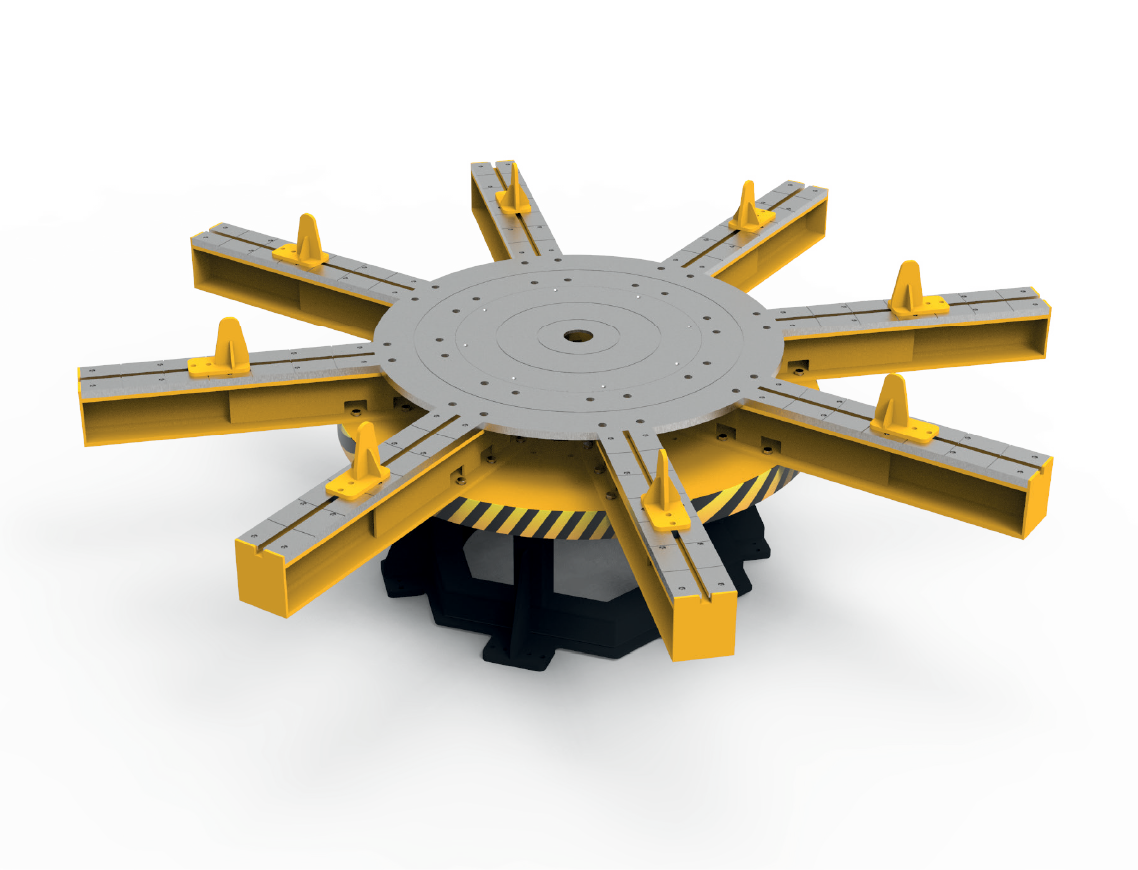

Rotary table positioner systems are mechanical systems used in welding and assembly operations to enable precise clockwise or counterclockwise rotation of workpieces. The system provides rotational movement on a horizontal axis, allowing workpieces to be held at the optimal welding angle. Commonly used in industrial applications where large and heavy workpieces need to be rotated, these systems enhance quality and efficiency in production processes.

Thanks to their precise speed control and powerful motors, rotary table systems deliver highly efficient power transmission. Their ability to integrate with automation systems allows them to operate in sync with column-boom systems and other welding equipment. Preferred for welding, grinding, assembly, and quality control operations, these positioners play a vital role in the industry in terms of both workplace safety and productivity.