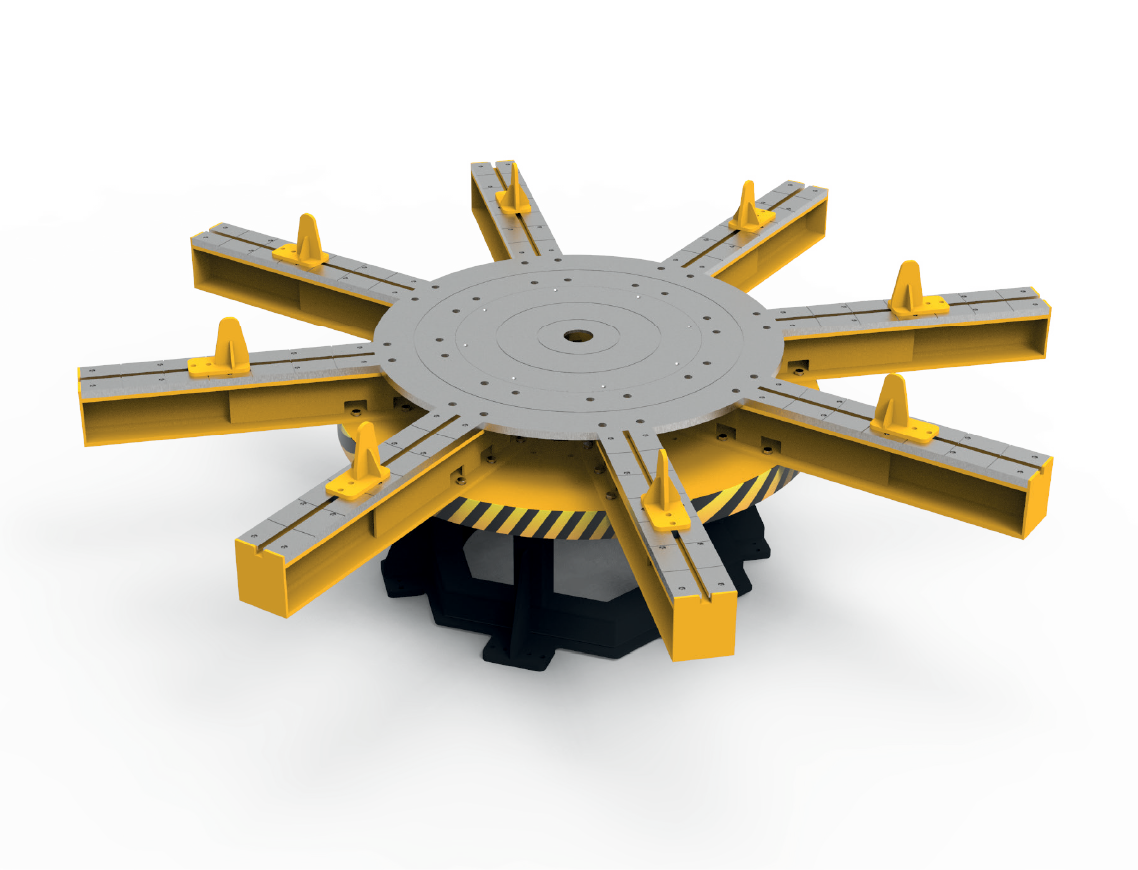

Rotary table positioner systems are mechanical systems that enable precise rotation of workpieces in clockwise or counterclockwise direction in welding and assembly processes. The system offers rotation in the horizontal axis and allows workpieces to be held at the optimal welding angle. It is widely used in industrial applications where large and heavy workpieces need to be rotated and improves quality in production processes.

Rotary table systems offer a highly efficient power transmission thanks to precise speed control and powerful motors. With the ability to be integrated with automation systems, the system can work in synchronization with column boom systems and other welding equipment. These positioners, which are preferred in welding operations, grinding, assembly and quality control processes, have gained an important place in the industry in terms of occupational safety and efficiency.