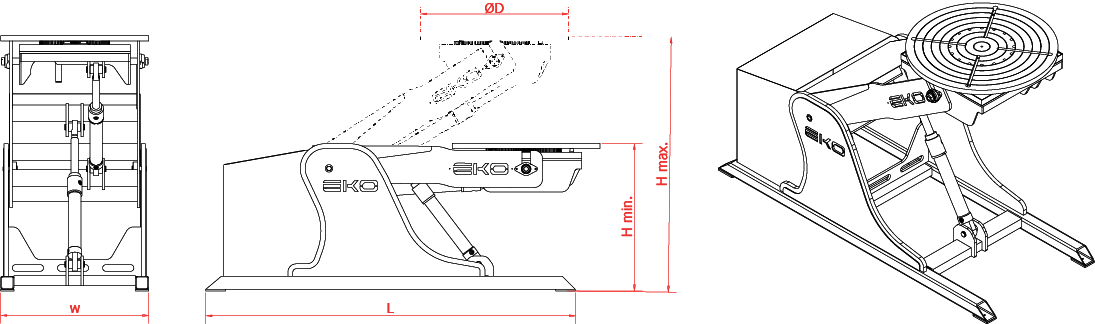

PH-hydraulic positioner systems are advanced mechanical equipment used in industrial production processes and provide safe and precise positioning of workpieces. These systems are equipped with hydraulic drive systems to perform operations such as rotation, angular positioning and height adjustment of large, heavy and complex workpieces.

Thanks to the hydraulic mechanism of the system, positioners with high carrying capacity; It increases efficiency in production processes by minimizing the need for manual intervention of operators in welding, assembly and processing processes.

These systems are generally preferred in heavy industry applications and provide precise positioning of workpieces by offering movement capability in different axes. The system moves with high precision thanks to hydraulic actuators, thus increasing quality in welding processes by providing vibration-free operation.

PH-hydraulic positioners offer a user-friendly interface with digital and analog control options, which facilitates operators’ control over the system. It provides a safe working environment with its low-voltage control system and thermal protection features. In addition, thanks to its integration into automation systems, it works synchronously with column boom systems and other welding equipment, making production processes more efficient.

PH-hydraulic positioner systems play a critical role in welding, grinding, assembly and quality control processes. At the same time, it offers great convenience to operators in modern production lines. These systems continue to offer effective and reliable solutions in every area of industrial production with the high carrying capacity and flexibility provided by hydraulic systems.