Circular welding systems are automation solutions that perform the welding of cylindrical or circular workpieces in a precise, controlled and continuous manner. These systems enable uninterrupted welding with axial rotation of workpieces such as pipes, tanks, pressure vessels, flanges, shafts and rotating parts.

The system is equipped with a precise speed control mechanism and automatic weld seam tracking systems, minimizing operator errors and helping to achieve repeatable and high quality welding results.

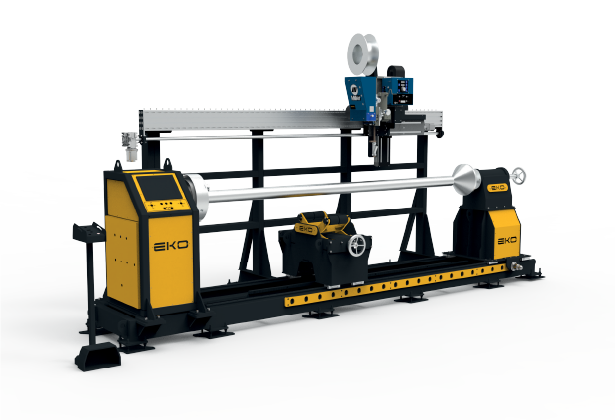

These systems work with motorized rotary tables, automatic mechanisms that carry the welding torches and PLC-powered control units. The rotation of the workpiece, combined with the fixation of the welding torch at the designated point, ensures that the weld seam is continuous and uniform. Different processes such as MIG, MAG, TIG or Submerged Arc Welding can be supported. Thus, it offers flexible solutions suitable for different industrial production requirements.

Circular welding systems offer great advantages compared to manual welding methods. Thanks to the automatic welding process, the seams on the workpieces become smoother, stronger and homogeneous. In addition, the system minimizes the error rate and reduces the waste rate, thus reducing production costs. While labor productivity increases, operator fatigue is minimized. At the same time, with its precise speed adjustment feature, it ensures that the welding seams are formed in accordance with the material properties and welding method.

Circular welding systems can be integrated with column boom systems, robotic welding units and rotary table systems. This integration increases productivity in industrial production lines and accelerates mass production processes. Widely used in many sectors such as pipe production, pressure vessel manufacturing, ship industry, automotive and machine production, these systems are an indispensable part of precision welding processes in industry.

Circular welding systems stand out as one of the cornerstones of modern industrial production, saving time and cost while increasing welding quality.

These systems have become more intelligent and precise with advancing automation technologies and continue to provide safe and efficient production solutions by optimizing industrial production processes.