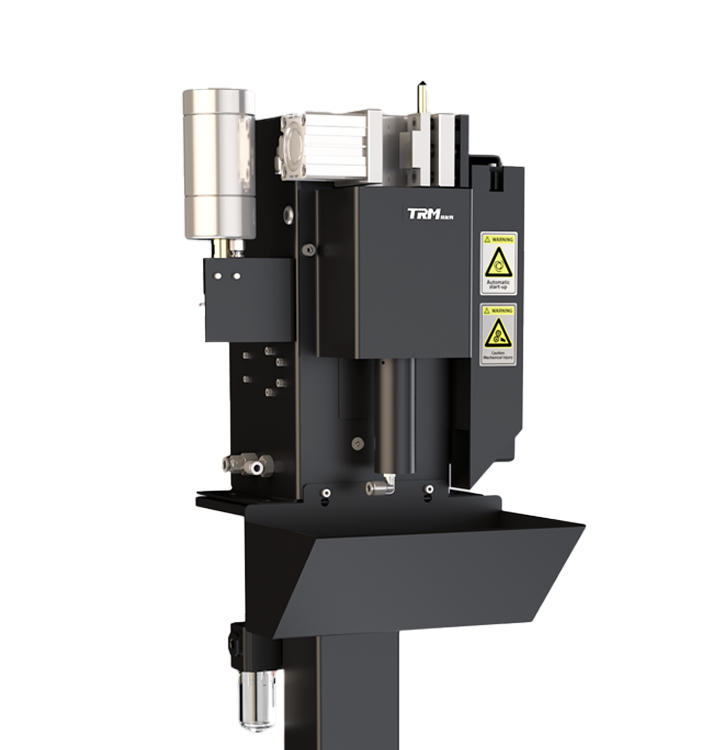

The Bilmer Sor TRM SC221A Torch Cleaning Station automates the maintenance and cleaning of welding torches, enhancing efficiency in production processes. This station optimizes torch performance and ensures uninterrupted operation. The SC221A model automatically cleans gas nozzles, extending torch life and increasing maintenance intervals. Additionally, it supports welding quality and process reliability through wire cutting and anti-spatter spray applications. Its compact design allows easy integration with various robot brands and types. Built with high-quality components, this station offers long-lasting, reliable performance while improving workplace safety and providing an environmentally friendly operation.

Designed to prevent common issues such as torch clogging and spatter buildup, the Bilmer Sor TRM SC221A features specialized cleaning mechanisms that ensure optimal torch performance before each welding operation. Its automatic cleaning cycle minimizes the need for manual maintenance and guarantees production continuity. Programmable control options enable easy adaptation to different production lines, offering maximum flexibility in welding operations. Operating with high speed and precision, this system prolongs torch lifespan and helps businesses reduce maintenance costs.