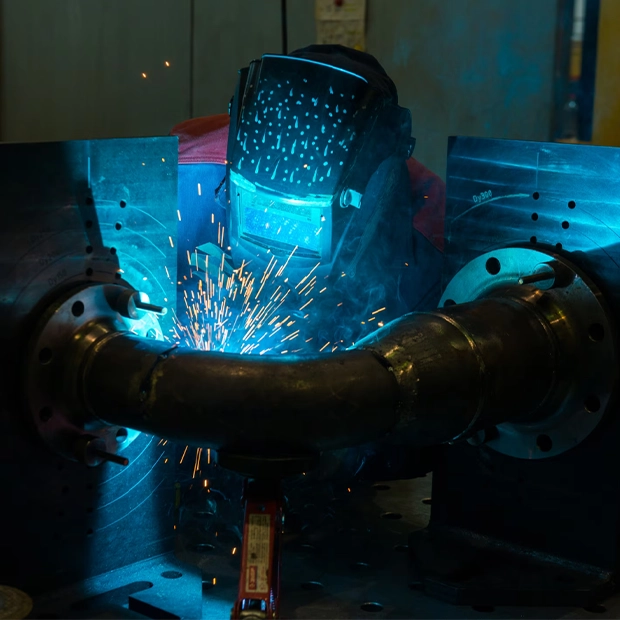

Submerged Arc Welding

Submerged arc welding stands out as an efficient welding method frequently preferred in industrial production processes. This method offers deep penetration and high weld quality, especially in the joining of thick materials.

Submerged arc welding takes its name from the special welding flux used in the process. This flux not only protects the weld area from external influences but also enhances arc stability. During the welding operation, as the wire electrode melts, the weld bead forms in a shielded environment beneath the flux. Its ability to operate at high speed with deep penetration makes it ideal for mass production. Moreover, the ease of integration with automated welding systems allows for labor savings and promotes standardization in weld quality.

What is Submerged Arc Welding?

Submerged arc welding is a method where the weld bead is formed under a special layer of flux, offering high efficiency and strong joints. Typically applied using automatic or semi-automatic systems, this method is commonly preferred for joining thick metal parts. During the process, the arc forms under the flux covering, protecting the weld pool from external effects and resulting in a stronger, smoother weld bead.

This welding method has a wide range of applications. It is particularly ideal for industrial welding processes requiring high penetration and deep welds. Compared to other methods, it provides less spatter and higher welding speed. These features offer significant advantages in large-scale production lines.

Advantages of submerged arc welding include:

Within the scope of heavy industrial welding solutions, it is widely used in areas such as shipbuilding, pipeline manufacturing, and steel construction.

For these systems to operate effectively, it is essential to use suitable welding machines, high-quality welding equipment, and proper welding consumables. To ensure efficient and long-lasting welds, all components must be compatible with each other.

Thanks to its high quality, speed, and efficiency, submerged arc welding has become an indispensable welding method in heavy industry projects. With the right selection of equipment and materials, this method provides great contributions to production processes.

Applications of Submerged Arc Welding

This method, which comes to the forefront in joining heavy-load-bearing and thick-sectioned materials, plays a critical role in industrial production processes.

The main areas where the submerged arc welding method is widely used include:

Provides strong and leak-proof welds in the joining of thick sheet plates.

Preferred in the manufacturing of tanks and boilers that require high strength.

Forms continuous and long weld seams in oil, natural gas, and water lines.

Ensures durability in bridges, viaducts, and large-scale construction frameworks.

Offers reliable solutions for long-lasting joints.

Frequently used in the circumferential welding of cylindrical structures.

Welding solutions for heavy industry also form the basis of industrial welding applications in sectors such as energy, automotive, and machinery production. Submerged arc welding is an indispensable technology in industries where structural durability and production speed are critical.

Frequently Asked Questions

It is generally applied on carbon steel, non-alloy, and low-alloy steels. It can also be used on stainless steel and some special alloys.

It is mostly applied using automatic or semi-automatic systems. Manual application is difficult and uncommon.

Essential welding equipment includes a welding machine, wire feeder, flux feeder, electrode wire, and suitable flux.

It has a smooth, wide, and uniform appearance. Thanks to the protective effect of the flux, the slag layer can be easily removed.

It quickly and efficiently joins thick parts with high quality. It is particularly ideal for industrial welding and demanding production environments.

For more detailed information and a quote about submerged arc welding, feel free to contact Eko Kaynak.