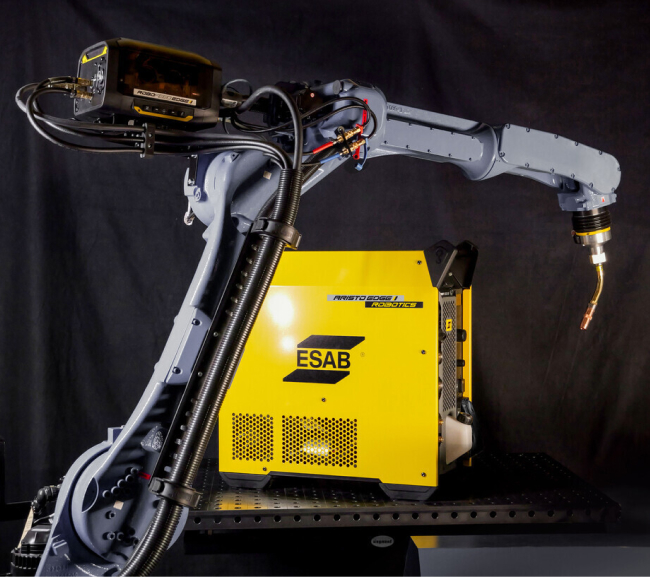

ESAB Mig/Mag MIG Welding Machine offers reliability and high performance in robotic welding applications. These machines can be seamlessly integrated with robotic systems to increase efficiency in industrial production processes. ESAB’s robotic welding solutions include a variety of models and features to suit different applications and needs. In particular, components such as robotic power units, wire feeders and torch cleaning stations have been developed to increase the efficiency and quality of automated welding processes.

ESAB Mig/Mag MIG Welding Machine provides superior weld quality and precise control features, enabling consistent and repeatable results in production lines. At the same time, these machines help reduce operating costs by providing energy efficiency and long-lasting performance. ESAB’s wide range of products are designed to meet the needs of different industries and applications.