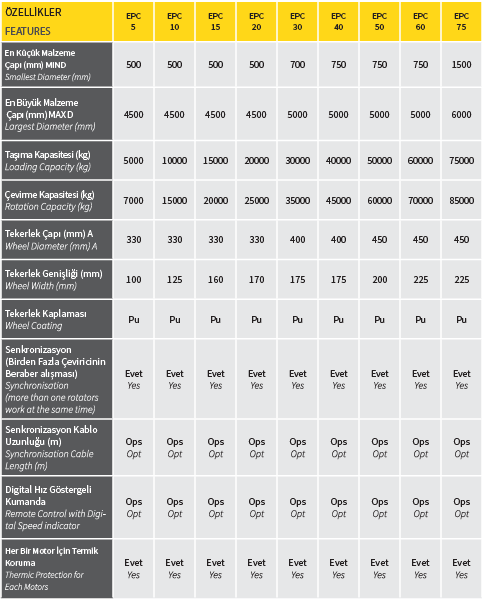

Conventional fit-up systems are mechanical systems that allow cylindrical workpieces to be rotated during welding, assembly and grinding processes. These systems are designed for workpieces with unchanging diameters or working in a fixed range and have a manually adjustable wheel structure.

The operator adjusts the distance between the wheels according to the diameter of the workpiece and makes the system suitable. These systems allow the rotation of pipes, tanks, pressure vessels and large metal cylinders, allowing welding operations to be performed more precisely and stably.

Conventional fit-up systems have high carrying capacity and are generally used in heavy industry applications. Steel or polyurethane coated wheels provide a vibration-free and stable rotation without damaging the surface of the workpieces. The sensitive speed control mechanism and digital speed indicator allow the operator to adjust the rotation speed of the workpiece. At the same time, the system can be easily managed with manual control options via remote control or panel.

Conventional fit-up systems can be integrated with automation systems and column-boom systems, thus providing a more efficient and safe workflow in production lines. It offers long-lasting use thanks to its low maintenance requirement and durable body structure.

These systems, which are widely used in industrial production in areas such as pipe production, shipbuilding, metal cylinder welding and pressure vessel manufacturing, are welding support equipment that offers significant advantages in terms of precision, durability and work safety.