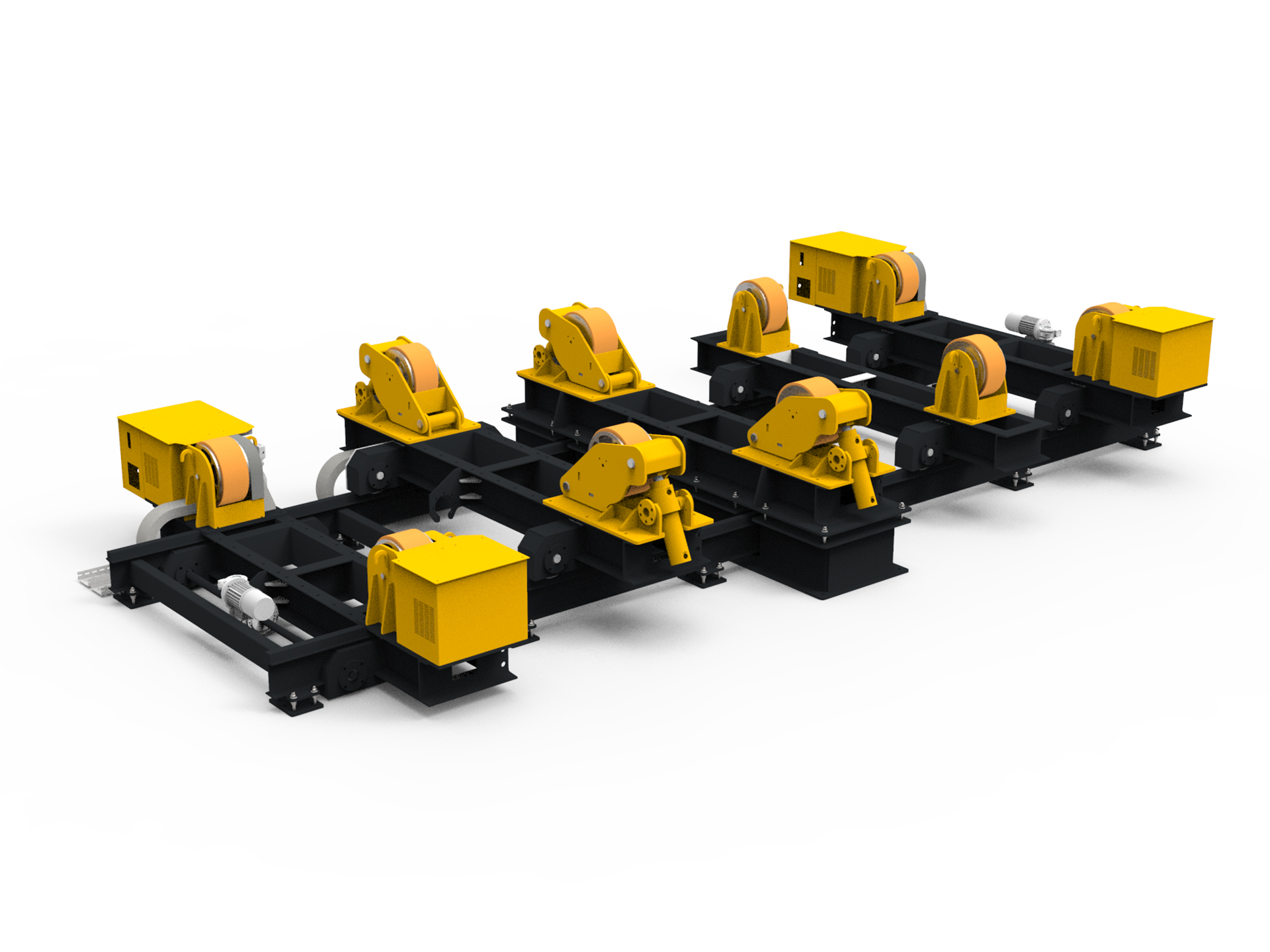

Conventional fit-up systems are mechanical systems that allow cylindrical workpieces to be manually adjusted and rotated during welding and assembly operations. These systems are designed to operate within a fixed diameter range and require manual mechanical adjustment by the operator to accommodate different workpiece sizes.

Conventional systems offer high load-bearing capacity and are commonly used in heavy industrial applications. The manually adjustable wheel spacing allows proper positioning of workpieces with varying diameters and lengths. These systems stand out as essential equipment in industrial production, enhancing quality and precision.