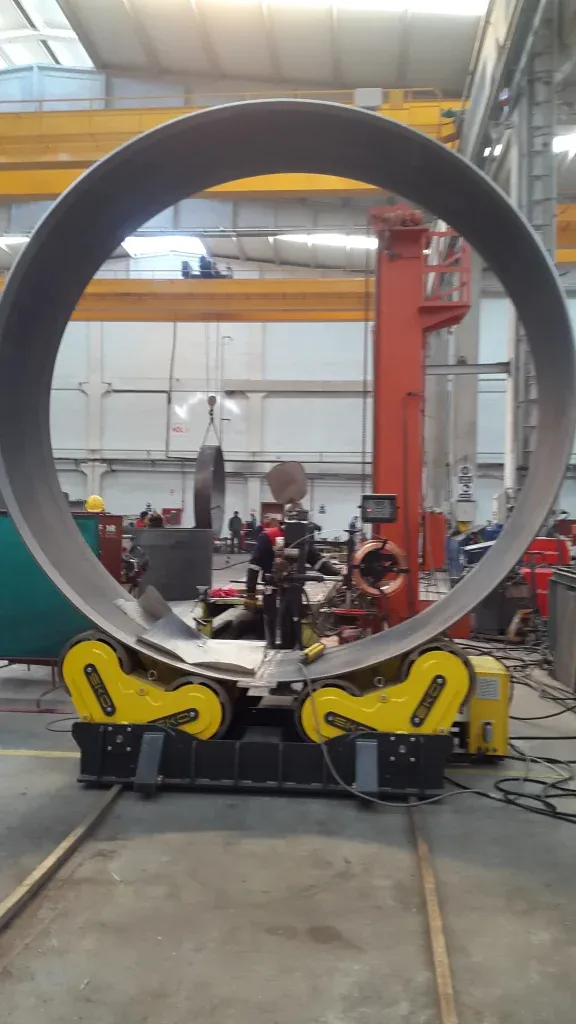

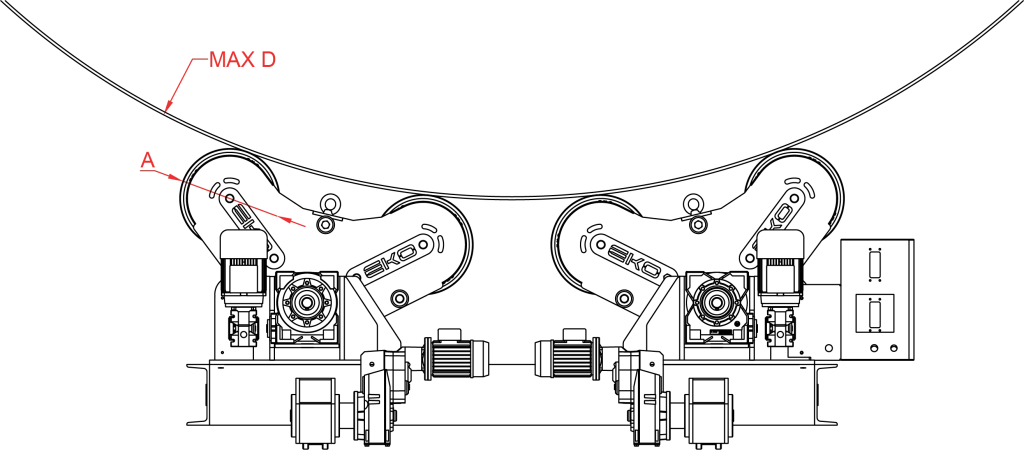

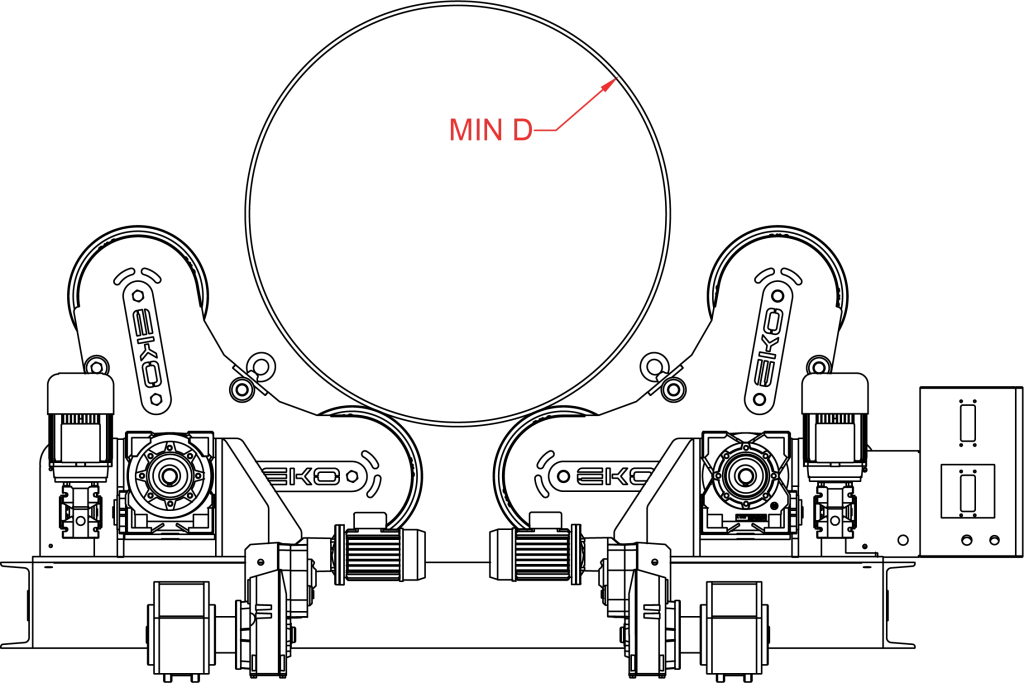

Self-aligning rotator systems are mechanisms that provide high precision during welding by automatically centering cylindrical workpieces of varying diameters and sizes. These systems do not require manual adjustment, as they automatically adapt to the diameter of the workpieces, minimizing the need for operator intervention.

Equipped with motorized drive mechanisms and hydraulic support units, self-aligning systems offer high load-bearing capacity. Polyurethane-coated wheels ensure smooth rotation of the workpiece during welding and are resistant to impacts. These systems are widely used in industrial applications such as pipe production, tank manufacturing, and welding of heavy industrial equipment.